Published - 25th Jul 2025

How Metaltech Precision delivers repeatable, tight-tolerance parts from Ø 2mm to Ø 32mm — trusted by OEMs in aerospace, medical, semiconductors and more.

In precision engineering, the smallest components often carry the greatest responsibility. From defence systems to aerospace actuators, semiconductor processing equipment to medical devices, quality, repeatability, and scale are essential.

When you’re sourcing small diameter parts at scale, performance and price must go hand-in-hand. That’s where sliding head machining excels and Metaltech Precision leads.

Based in the UK, Metaltech Precision is a specialist machining services partner in sliding head computer numerical controlled (CNC) machining. We manufacture complex, tight-tolerance small turned parts in volumes from hundreds to hundreds of thousands. Our production range covers diameters from 2mm to 32mm, with full traceability and quality assurance backed by AS9100 accreditation. We combine speed, consistency and accuracy to deliver performance you can trust.

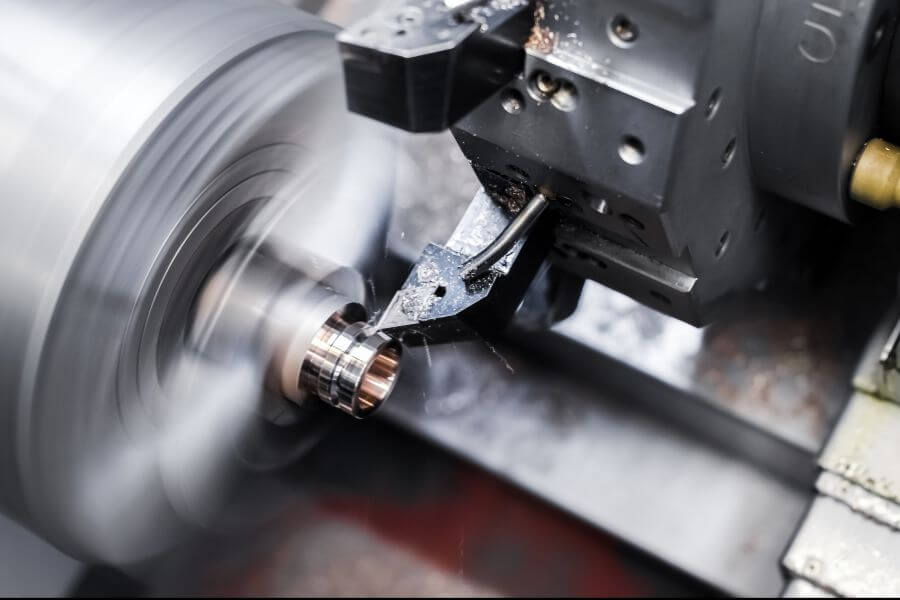

Sliding head machining (also known as Swiss-turn machining) is a CNC turning process designed for long, slender and intricate components. Unlike conventional lathes where the tool moves and the bar stock remains stationary, sliding head machines advance the bar through a guide bushing, keeping the cutting area extremely close to the material support.

This unique setup provides several clear advantages:

At Metaltech precision, we use sliding head technology to deliver tight tolerance turned parts in demanding materials, with features including undercuts, threads, cross-holes and more — all produced in a single operation, without the need for secondary processes.

In recent years, Metaltech Precision have increased our sliding head capacity to 13 state-of-the-art machines through the acquisition of NC Precision, a company with a legacy in manufacturing small-diameter complex components. Our investment in modern sliding head machinery allows us to optimise cycle time, tool wear and process repeatability to deliver precision components at scale. With in-house tooling expertise and CAM (Computer-Aided Manufacturing) programming, we support customers at every stage of production.

Metaltech Precision’s sliding head machining capabilities

At Metaltech Precision, our commitment to investment in technology is central to delivering exceptional results. Our dedicated sliding head machining capability is backed by a comprehensive plant list that includes machining centres from leading brands such as Citizen, Doosan and Mazak, with advanced support equipment for finishing and inspection. This allows us to scale production efficiently while maintaining the highest standards of precision.

View our full plant and machinery list

Key sliding head machining capabilities at Metaltech include:

Our approach allows customers to benefit from high-volume output without compromising on accuracy or finish quality. High-performance CNC turning centres with automated feeders form the backbone of our lights-out production environment, enabling us to meet increasing demand across performance critical applications.

Ongoing investment in new machinery

We continually invest in the latest machinery to stay at the forefront of advanced CNC machining, supported by high quality inspection and quality control.

For example, Metaltech’s investment in the new Quantum X FaroArm, a portable coordinate measuring machine (CMM) significantly enhances the accuracy of inspection practices. This state-of-the-art, portable technology is designed to probe or scan, with articulated measurement arms that are significantly more versatile than fixed CMMs and can access harder-to-reach locations – delivering up to 15% accuracy increase against previous models. When every micron matters, this is significant, and highlights our commitment to consistent quality assurance.

We partner with customers in sectors where precision, traceability and trust are non-negotiable. Here’s how our services support performance-critical applications:

Aerospace precision components

In aerospace, even the smallest parts play a critical role in safety and performance. We manufacture components such as sensor housings used in actuation systems, avionics and engines, fasteners, fittings and control assemblies.

As a reliable UK sliding head subcontractor, we help aerospace engineers keep production on track without compromising quality.

Semiconductors and electronics

The demand for miniature machining in semiconductor and electronics systems is growing rapidly. We support semiconductor production and electronics OEMs by supplying small components such as small diameter connectors, miniature sensor housings, precision pins for processing equipment and custom fixtures.

For both R&D tooling and mass production, our CNC sliding head machining delivers precision at speed — essential for just-in-time supply chains.

Defence CNC machining services

Metaltech supports Tier 1 defence contractors with repeatable small component machining for land, air and naval systems. Applications include submarine shafts, bushes for land vehicles, structural fittings, threaded inserts, precision spacers and fasteners.

We’re a trusted partner for defence projects that demand accuracy, confidentiality and consistent delivery.

Industrial automation and automotive electric motors

From sensor brackets to drive shafts, our small turned parts help drive the next generation of automation and electrification.

If your design requires scalable precision, we can help bring it to life.

Medical device component machining

Medical components require absolute consistency and clean, burr-free finishes. Metaltech Precision can deliver small, intricate components such as small surgical screws, cannula fittings, diagnostic housings and implant components.

Whether your parts are destined for operating theatres or patient diagnostics, we ensure every turned component meets the strictest standards.

Certified to deliver: Metaltech’s accreditations

At Metaltech Precision, quality is built into everything we do. Our work is backed by internationally recognised certifications that give our customers peace of mind and ensure compliance in the most demanding sectors.

Our current certifications:

We also use the standard AS9102 FAIRs (First Article Inspection Report) template across all sectors if requested, evidencing that our manufactured products conform to design requirements.

Why this matters for you:

Working with a certified supplier helps you meet your own compliance obligations and supports the performance of every component you receive.

Metaltech Precision machines a broad range of engineering metals, each chosen for their mechanical and physical properties. Our team can advise on material selection to meet your performance and cost targets.

Commonly machined materials:

By combining material versatility with process expertise, we produce complex turned components that meet the highest functional and environmental demands.

We know that procurement and engineering teams need:

By choosing Metaltech Precision, you benefit from:

Whether you’re trying to improve component design, lower unit cost, or simply reduce project stress, our team is here to help.

Metaltech Precision is proud to be part of Expromet Technologies Group, a UK-based group of advanced manufacturing companies that deliver engineered metal components and assemblies for global OEMs.

Being part of the group gives our customers more than just precision machining — it offers access to a diverse range of casting and engineering capabilities, all underpinned by a shared commitment to quality, technical expertise, and responsive service.

Expromet group companies and their capabilities:

Metaltech Precision

We specialise in CNC machining, particularly sliding head turning and multi-axis milling, with a focus on small, complex components in high volumes. Our capabilities include:

Haworth Castings

Experts in high-integrity sand and gravity die casting, Haworth Castings produces components for aerospace, defence, energy and industrial markets. Capabilities include:

Investacast

A leading provider of investment casting, pressure die casting and CNC machining, with both UK and international production routes. Investacast is known for:

Expromet Asia Inc

Opened in the Philippines in 2024, this facility expands the group’s capacity to serve global customers with machined components, while supporting cost-sensitive production and strategic reshoring initiatives.

By working with Metaltech Precision, you gain access to this integrated group of engineering specialists — whether you need a single CNC-turned component or a fully machined and cast assembly with global supply support. It’s manufacturing synergy that works for you.

Looking for a consolidated supplier for cast and machined parts? Expromet can help streamline your supply chain.

Our clients choose us because we combine technical precision with reliable service. What sets us apart is:

If you’re looking for a cost-effective CNC machining partner for small parts, Metaltech Precision is here to help. From one-off development to full-scale production, we deliver what matters: precision, reliability and scale.

What is sliding head machining used for?

Sliding head machining is ideal for producing small, high-precision turned parts with complex features, especially in large volumes. It’s used across industries like medical, aerospace, semiconductors, and defence for components such as connectors, pins, valves, housings, and fasteners.

What size parts can Metaltech Precision machine?

We manufacture turned parts ranging from 2mm to 32mm in diameter, using multi-axis Swiss-type sliding head machines. This makes us ideally suited for small diameter components with tight tolerances and complex geometries.

Can sliding head machining reduce cycle times?

Yes. Sliding head lathes are designed for efficient, high-speed machining, and our tooling, programming, and lights-out production strategies help significantly reduce machining cycle time, especially on repeat or long-run batches.

Is Metaltech a UK-based sliding head subcontractor?

Yes, Metaltech Precision operates from our facility in the UK and is part of Expromet Technologies Group. We are a reliable UK sliding head subcontractor, providing quality machining with full traceability, responsive service, and no cross-border delays.

What industries use sliding head machined components?

Sliding head machining is widely used in:

Can you produce repeat batches of small parts?

Yes. We specialise in repeatable, high-volume manufacturing. Our sliding head machines are optimised for consistent performance across long runs, with in-process inspection to maintain quality throughout production.

What materials do you machine?

We work with a wide variety of metals, including:

We can advise on material selection to balance cost, machinability and performance.

Do you offer end-to-end support?

Yes. From prototype to production, we support every stage of the project. Our team works closely with customers on design for manufacture, material selection, and batch planning to ensure reliable delivery.

Can you help with tight tolerance requirements?

Absolutely. Sliding head machining excels at maintaining tight concentricity and dimensional tolerances. We also perform in-process measurement and final inspection using calibrated equipment to ensure every part meets spec.

How does being part of Expromet Technologies Group benefit me?

As part of Expromet Technologies Group, Metaltech Precision offers more than CNC machining. You gain access to group-wide capabilities including casting (sand, investment, pressure die), machining, and international supply support, all under one trusted engineering umbrella.

If you have a project, talk to our experienced sales team

Contact us