Published - 4th Dec 2025

New Aberlink Azimuth boosts Metaltech’s high-accuracy inspection capability

Accuracy is key to precision CNC machining. In performance-critical sectors such as aerospace, defence, rail and energy, customers rely on machined parts to meet demanding tolerances and perform reliably in challenging environments. As components become more complex, and expectations on quality continue to rise, accurate inspection becomes ever more important.

Expert CNC machining capability must be matched by robust inspection. A manufacturing partner’s reliability depends on how well they can verify every critical feature, so investment in advanced metrology is essential. At Metaltech Precision, continuous improvement is central to how we work. Our latest investment in the Aberlink Azimuth coordinate measuring machine (CMM) strengthens our ability to deliver consistent quality for performance-critical applications.

A coordinate measuring machine provides accurate, repeatable measurement of a component’s dimensions, surfaces and geometric features. It does this using a probing system that moves through three axes to capture data points. CMMs are relied on to verify tight tolerances, confirm complex geometries and validate machined features that cannot be checked reliably with manual tools. They are used for first-off inspection, in-process checks and final verification of CNC machined components before shipment.

For customers, this means greater confidence in the dimensional accuracy of every part, and the assurance that quality is controlled throughout the manufacturing process. For suppliers working in regulated sectors, such as aerospace and defence, this level of verification is essential – reliable, traceable inspection underpins the integrity of the entire production system.

Our machining capability includes larger, heavier and more complex parts, often with multi-operation CNC machining routes. These components can include intricate surfaces, deep features or precise alignment requirements. As complexity increases, so does the need for accurate measurement. Advanced metrology supports tighter process control, reduces variability and helps eliminate non-conformance.

“For industries producing high-value parts to high tolerances, such as the aerospace, motorsport and space sectors, the measurement and confidence metrology can provide is vital and should not be overlooked.” The Importance of Metrology in Manufacturing (MSP 2024)

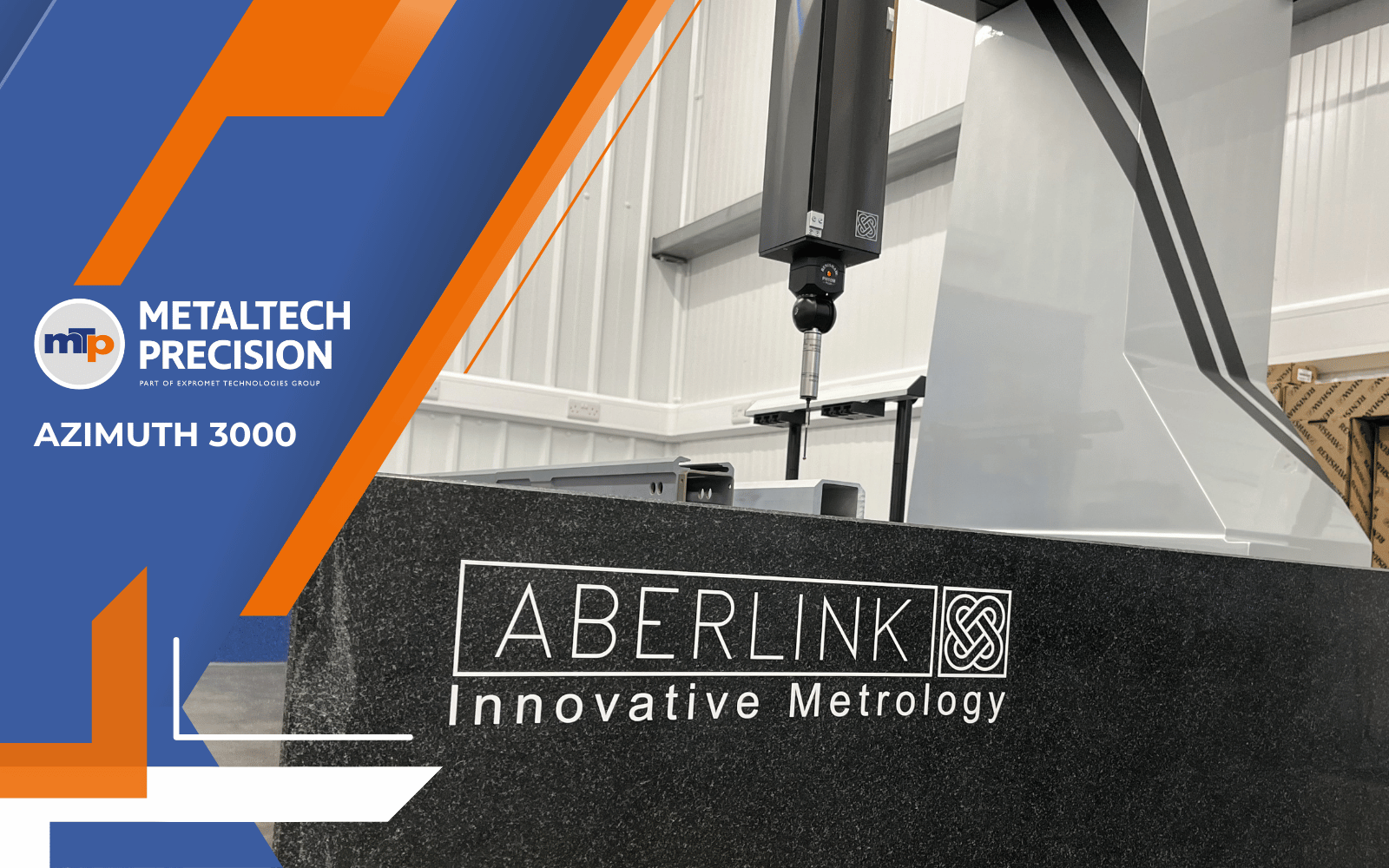

The Aberlink Azimuth is a large-format bridge CMM designed to offer high accuracy across a generous measuring volume. We selected this machine for its rigidity, reliability and advanced probing capability: features that make it particularly well suited to the work we undertake.

Key benefits of the Azimuth include:

We have opted to include the SP25M scanning probe, which uses an isolated optical metrology transducer system to enable extremely accurate measurements to be taken with the stylus in continuous contact with the feature being inspected.

“The Azimuth brings new capability to our inspection process,” says Andrew Fielding-Hunt, QHSE Manager at Metaltech Precision. “In particular, the SP25 scanning probe provides continuous measurement rather than single-point checks, giving us better accuracy on features like runout and concentricity and the 3000mm Y axis travel unlocks new potentials; it’s a significant improvement for verifying complex components.”

This investment complements our existing inspection resources and adds a new level of capability, ensuring we can measure precision machined parts with confidence, no matter how challenging the requirements.

The addition of the Azimuth CMM brings several clear benefits:

This investment reinforces our position as a trusted partner for high-accuracy CNC machining for performance-critical applications.

The Azimuth adds to our established range of inspection equipment, giving us full coverage across different component sizes, geometries and production requirements. Our temperature-controlled inspection facility houses several coordinate measuring machines, along with specialist tools for detailed dimensional and surface verification. Our equipment includes:

Together, these systems support accurate, repeatable quality control for everything from small, detailed parts to large, heavy or complex components. This breadth of capability ensures we can measure critical features at every stage of production, from first-off checks to final verification.

For precision manufacturing, especially in CNC machining, engineers recognise that CMM inspection also supports efficient processes:

“Precision metrology plays a pivotal role in modern manufacturing processes by ensuring the attainment of high-quality standards and the optimization of production efficiency” (The Role of Precision Metrology in Enhancing Manufacturing Quality: March 2024 Engineering Science & Technology Journal)

With more accurate data available at every stage we can improve efficiency, reducing scrap and rework by identifying issues early. For customers operating in sectors where any deviation can result in costly downtime or safety concerns, this level of precision is vital.

State-of-the-art CMMs provide valuable data that can be used to refine machining processes. By analysing measurement results, we can validate tooling strategies, confirm the stability of setups and improve overall manufacturing consistency.

The Azimuth contributes directly to these goals, strengthening our capability to continually improve our machining and inspection processes.

CMM capability is part of our wider machining services for metal components. Metaltech Precision provides a broad range of in-house machining and fabrication services, including:

This combination allows us to manage projects from initial machining through to inspected, ready-to-use components. With extensive in-house capacity and the ability to work with a wide range of materials, including exotic alloys, we provide a reliable, efficient service for customers across multiple sectors.

Accurate measurement is central to precision engineering. As components become more complex and expectations on quality continue to rise, advanced metrology is essential.

Our investment in the Aberlink Azimuth strengthens our inspection capability and supports our commitment to delivering consistent, high-quality machined and fabricated components.

For customers, it means greater confidence in every part we produce — from the simplest turned feature to the most complex multi-operation assembly. It also reinforces our position as a dependable, UK-based manufacturing partner for performance-critical applications.

“Continuous investment in metrology shows our long-term commitment to customers,” confirms Chris Thompson, Managing Director, Expromet Technologies Group. “Accuracy underpins everything we do, and expanding our CMM capability ensures we can support complex, performance-critical components with complete confidence.”

If you need a reliable CNC machining partner with proven inspection capability, our team can help. To discuss your project or request a quotation, please contact Metaltech Precision.

CMM inspection uses a coordinate measuring machine to verify the dimensions, geometry and tolerances of machined components. It ensures each part matches the required specification and provides accurate, repeatable measurement data.

Performance-critical sectors, such as aerospace, defence and marine, require tight tolerances and full verification. CMM inspection provides the precision and traceability needed to confirm that every feature meets the design intent.

CMMs can inspect a wide range of components, from small, detailed parts to large, complex assemblies. The Azimuth’s large-format capability allows us to measure bigger and heavier components with high accuracy.

The Azimuth provides a larger measuring envelope, advanced scanning through the SP25 module and improved accuracy on features such as runout, concentricity and bore geometry. It enhances our ability to verify complex parts.

Traditional probing captures individual points on a surface. Scanning collects continuous data as the probe tracks the feature, offering better visibility of form, roundness and surface condition. This is useful for identifying issues such as ovality.

CMM inspection provides consistent measurement, reduces variation and helps identify issues early. It supports first-off inspection, in-process checks and final verification, improving confidence in every batch.

All CMMs use Aberlink for probing, whilst CAM2 is used to support the blue laser scanning on the FARO arm.

Accurate measurement data helps refine machining processes, validate new tooling or setups and improve repeatability. It reduces scrap and rework while strengthening long-term process stability.

We supply many performance-critical sectors, including aerospace, defence, energy, marine, and rail — all industries where accurate measurement, traceability and consistent quality are essential.

Yes. We provide detailed dimensional reports, first article inspection (FAI) data, full PPAPs with our supporting HighQA software, and full traceability to support customer and regulatory requirements.

If you have a project, talk to our experienced sales team

Contact us